Permanent Magnet Stepper Motors

Permanent magnet (PM) stepper motors provide incremental positioning capabilities and excellent zero speed holding torque in a cost-effective package. Step motors are used in many different applications that require accurate positioning and/or speed control. The number and frequency of input pulses control the respective rotational position and speed of a stepper motor by moving the motor in small rotational increments, called steps. PM Stepper motors consist of a permanent magnet rotor inside of a stator housing that contains the phase windings of the motor which create the rotating electromagnetic field that rotates the rotor.

PM stepper motors offer higher torque and lower cost than hybrid or variable reluctance stepper motors, but speeds are limited and their position resolution is higher (less precise). Our stepper motor specialists will assist you in defining the optimal stepper motor to meet your exact application needs.

Product Attributes

- 4 mm to 42 mm OD frame sizes

- 3, 5, 12, 24VDC input voltage versions

- 5⁰, 9⁰, 15⁰, 18⁰ step angle options

- 2 to 700 mNm holding torque range

- 0 – 5500 pulse per second speed range

- Unipolar, bipolar versions

- Gear motor options (5 – 35 mm OD)

- Customizable

Benefits

- Great position and speed control

- High holding torque

- Long operating life

- Optimized to unique application requirements

- Cost-effective

- Compact

Applications

- Dosing Equipment

- Linear Actuators

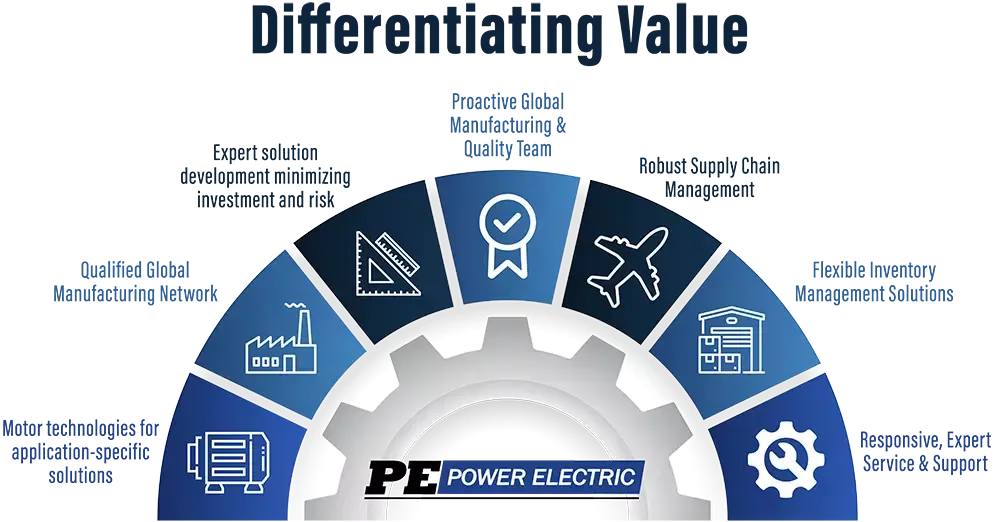

Design. Sourcing. Quality. Logistics. Support.

Request a Quote

Request a Quote