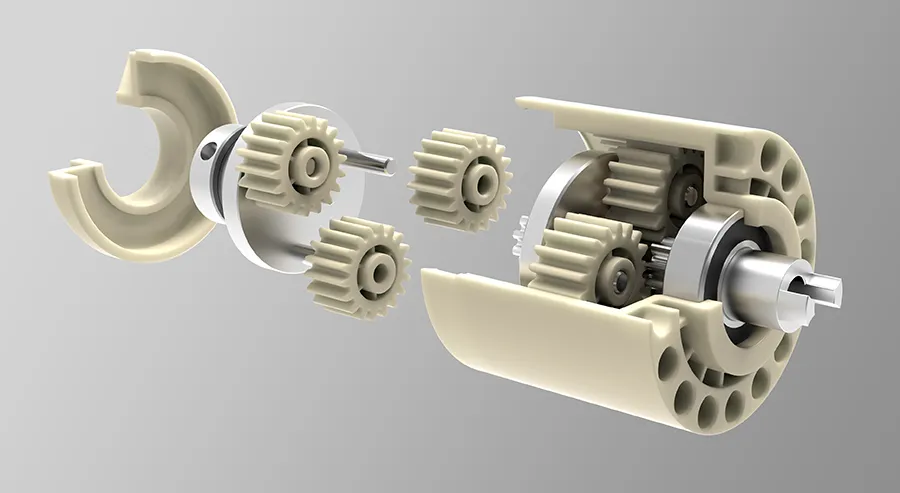

Plastic Planetary Gear Motor Advantages and Disadvantages

Plastic planetary gear motors can provide a wide range of gear reduction ratios in a compact package, combining high strength, low noise, and great value. They have one or more stages of gear reduction, all in line with the motor shaft with gears made of plastic. The outer body or casing can also be made of plastic. Like metal gear planetary gearheads, each stage has three or four gears in mesh, providing considerably greater strength than simple spur gearheads.

Advantages of Plastic Planetary Gear Motors Compared to Metal Planetary Gear Motors

Lightweight: Plastic gears are generally lighter than metal gears, making plastic planetary gear motors lightweight and compact. This characteristic is advantageous in applications where size and weight are critical factors, such as in portable devices or equipment with limited space.

Low Noise and Vibration: Plastic gears have the potential to provide quieter and smoother operation compared to metal gears. The inherent damping properties of plastic help reduce noise and vibration, making plastic planetary gear motors suitable for applications where noise reduction is important, such as in medical equipment or consumer electronics.

Corrosion Resistance: Plastic gears generally resist corrosion and do not require lubrication. This resistance to corrosion makes plastic planetary gear motors suitable for use in environments with exposure to moisture, chemicals, or other corrosive substances.

Cost-Effective: Plastic gears can often be produced at a lower cost than metal gears. Plastic planetary gear motors provide a cost-effective solution for applications where budget constraints are a consideration.

Customization and Design Flexibility: Plastic gears can be easily molded into complex shapes, allowing for design flexibility and customization. Manufacturers can tailor the gear profiles, sizes, and ratios to meet specific application requirements, providing optimized performance and efficiency.

Non-Magnetic Properties: Plastic gears are non-magnetic, which can be advantageous in certain applications where magnetic interference needs to be minimized, such as in medical imaging devices or sensitive electronic equipment.

Wide Range of Applications: Plastic planetary gear motors find applications in various industries, including automotive, robotics, home appliances, office equipment, healthcare, and more. They are suitable for tasks that require precise motion control, torque transmission, and speed reduction.

Plastic planetary gear motors may have limitations in terms of load capacity and maximum torque compared to metal gear counterparts. Therefore, it is essential to carefully assess the specific application requirements and consult with the manufacturer or supplier to determine the suitability of plastic planetary gear motors for your intended use.

While plastic planetary gear motors have their advantages, they also come with several disadvantages when compared to metal planetary gear motors. Here are some of the key drawbacks:

Disadvantages of Plastic Planetary Gear Motors compared to Metal Planetary Gear Motors

Strength and durability: Metal planetary gear motors are generally stronger and more durable than their plastic counterparts. Metal gears can handle higher torque and are less likely to deform or break under heavy loads.

Heat resistance: Metal gears have better heat resistance than plastic gears. When exposed to high temperatures, plastic gears can melt, deform, or lose their structural integrity. Metal gears can withstand higher operating temperatures without significant performance degradation.

Precision and accuracy: Plastic gears are generally less precise and accurate than metal gears. Metal gears can be machined to tight tolerances, ensuring consistent and reliable performance. Plastic gears, on the other hand, may have slight variations in dimensions, leading to increased backlash and reduced overall precision.

Longevity and lifespan: Metal planetary gear motors typically have a longer lifespan than plastic gear motors. Metal gears are more resistant to wear and fatigue, making them suitable for continuous and heavy-duty use over an extended period.

It's important to note that the specific application and requirements will dictate whether plastic or metal planetary gear motors are more suitable. Each material has advantages and disadvantages, and the choice should be based on load requirements, operating conditions, cost considerations, and desired lifespan.

Molding quality gears of plastic materials is very much a specialty. Power Electric works with top suppliers who specialize in unique plastic planetary gear motors. Contact us now to jointly develop a custom plastic planetary gear motor for your application.

Request a Quote

Request a Quote